Every major construction project begins with a promise: a vision of solid infrastructure that will last decades. But what happens when that promise starts to crack, literally and figuratively? Construction defects are more common than many realize, and in civil, heavy, and underground construction, their consequences can be enormous. Whether the issue lies in faulty design, poor materials, or improper workmanship, these problems can lead to delays, legal disputes, and massive financial losses. That’s where a seasoned civil, heavy, and underground construction expert witness becomes essential, someone who can bring clarity and authority to complex cases.

In this article, we’ll explore what causes construction defects, how they’re investigated, and why expert witnesses are vital to achieving fair, evidence-based resolutions. Along the way, we’ll share insights into how to prevent issues before they ever reach the courtroom.

Understanding Construction Defects and Their Impact

At its core, a construction defect is any deviation from design specifications, code requirements, or accepted standards that compromises the integrity or functionality of a structure. In smaller projects, a defect might be a cosmetic nuisance. In civil or underground construction, however, the stakes are far higher. A misplaced conduit or a poorly compacted trench can lead to systemic failure, environmental hazards, or even endanger lives.

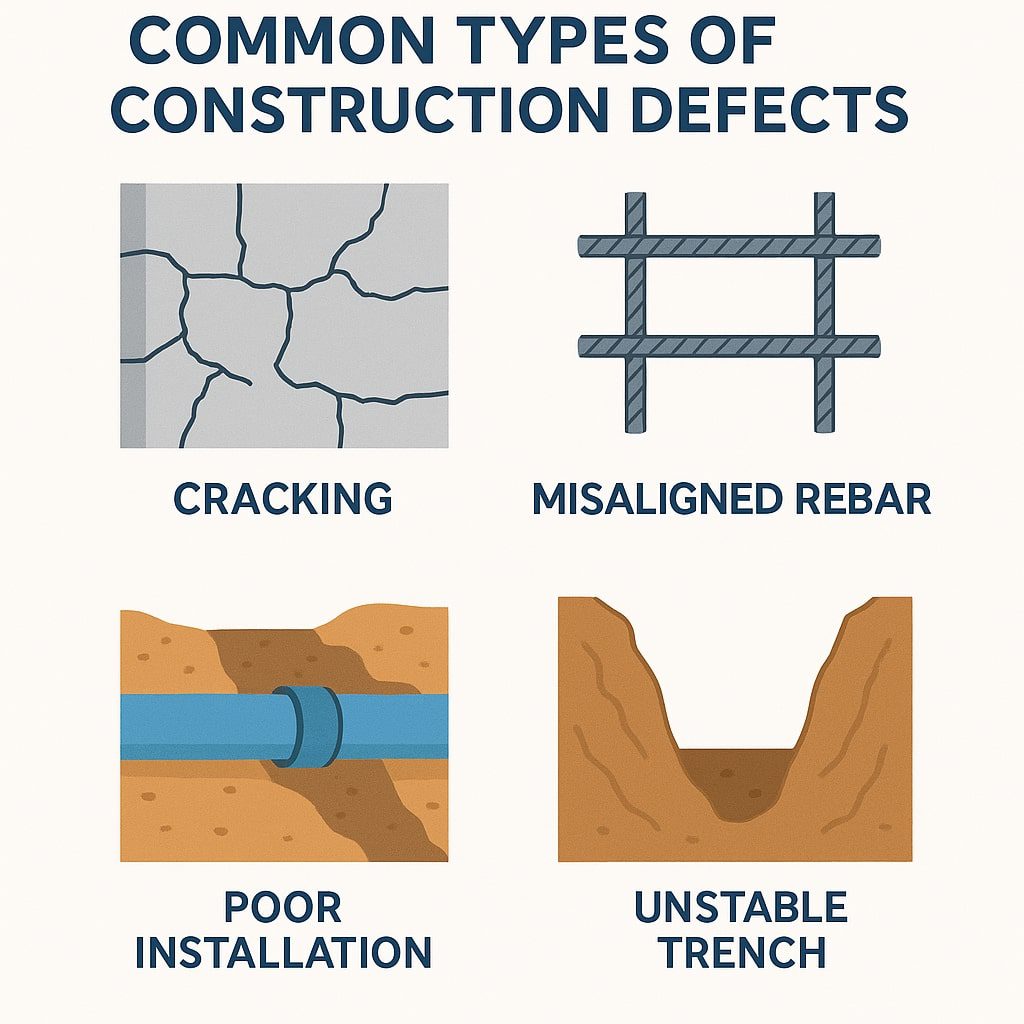

Defects usually fall into a few main categories: design flaws, workmanship errors, material failures, and unforeseen subsurface conditions. Each can cascade into bigger problems, like cracks in retaining walls, water intrusion into fiber optic vaults, or premature pavement settlement. Once these issues arise, they often trigger insurance claims, litigation, and costly repairs.

Common Types of Construction Defects

- Design flaws: Engineering miscalculations, incomplete plans, or conflicting specifications.

- Workmanship issues: Misaligned installations, poor consolidation of concrete, or rushed finishing.

- Material failures: Use of low-grade or incompatible materials that deteriorate under load or moisture.

- Subsurface problems: Inadequate soil stabilization, groundwater intrusion, or unexpected conditions below grade.

How Defects Affect Civil and Heavy Construction

Beyond cost and schedule overruns, defects can impact safety, reputation, and long-term performance. Think about the ripple effect of a misinstalled drainage line, minor at first, but potentially disastrous as erosion undermines a road or tunnel lining. For public works and large infrastructure, these failures can have significant community and legal consequences.

The Role of Expert Witnesses in Construction Defect Cases

When disputes arise, attorneys and insurers turn to experts who can make sense of the chaos. A qualified expert witness doesn’t just explain what failed, they illustrate why it failed and who is responsible. Their investigation bridges the gap between technical evidence and legal argument.

Construction expert witnesses analyze everything from drawings and contracts to soil data and test results. They reconstruct the story of the project: what should have happened, what did happen, and how the deviation caused measurable damage. During litigation or arbitration, they often serve as the voice of reason, translating complex engineering into clear, courtroom-ready testimony. For end-to-end support, many teams rely on litigation support services to strengthen their technical arguments.

What Construction Expert Witnesses Do

These professionals conduct forensic investigations, compare field findings with standards and codes, and prepare detailed reports. They may perform load testing, defect mapping, or failure simulations to confirm causation. Their goal is always the same, deliver unbiased, defensible conclusions backed by evidence.

Why Expertise Matters in Heavy and Underground Construction

Not all construction environments are equal. Underground work introduces unique risks like groundwater, soil pressure, confined spaces, and live utilities. Only an expert familiar with these conditions can assess whether shoring was adequate or if trench collapse was preventable. This specialized understanding can make or break a case in court.

Common Defect Issues in Utility and Underground Construction

Imagine a fiber optic network that keeps dropping signal weeks after installation. Or a manhole structure that begins leaking groundwater months into service. These aren’t isolated problems; they stem from specific defects in workmanship or materials. Telecommunications and electrical infrastructure are particularly sensitive to small installation errors that can lead to big failures.

Civil and heavy projects face their own pitfalls: uneven trench backfill, unstable embankments, or poorly poured concrete pads. Each requires a tailored forensic approach. Specialists in trenchless and underground construction discovery bring the insight needed to document these failures with accuracy and authority.

Telecommunications and Fiber Optic Projects

Issues in telecom often involve improper conduit alignment, substandard sealing, or fiber bends that exceed manufacturer limits. Over time, such flaws lead to water intrusion, attenuation, or even total network loss. A fiber optic expert witness can verify testing protocols, validate installation records, and pinpoint where and when compliance broke down.

Electrical and Civil Infrastructure Defects

Electrical infrastructure demands consistent grounding, correct phasing, and durable enclosure protection. Even a small misstep can cause corrosion or catastrophic shorting. Civil defects, meanwhile, often stem from rushed earthwork or inadequate compaction. Thorough site inspections and early expert involvement can reveal these problems before they escalate into full-blown disputes.

Investigating and Proving Construction Defects

Investigating a defect is much like detective work, it requires curiosity, patience, and technical precision. The process begins with documentation: reviewing contracts, submittals, and test reports, then conducting methodical site evaluations. Photos, samples, and measurements become the clues in reconstructing the story of failure.

Modern experts employ a range of tools including 3D scanning, nondestructive testing, and forensic modeling. Once data is gathered, they connect observations to contractual obligations, code requirements, and industry standards. The outcome is a factual narrative that supports or refutes claims of negligence. When accidents or sudden failures occur, specialized incident analysis experts help identify whether human error, environmental conditions, or equipment malfunction was at fault.

The Expert Witness Process

The work doesn’t end with analysis. Experts prepare detailed reports, visual exhibits, and sometimes demonstrative models that explain how and why a defect developed. In depositions or court, they simplify technical details so decision-makers can grasp the issues without losing accuracy. Many liken the process to “teaching the science behind the structure.”

Collaboration with Attorneys and Insurers

Successful outcomes often depend on strong collaboration between the expert and legal counsel. By clarifying facts early, experts can help shape discovery requests, frame arguments, and even promote early settlement. In insurance contexts, their findings can validate claims or mitigate liability before a case reaches litigation.

Preventing Future Defects Through Expert Consultation

Here’s a question worth asking: how many construction disputes could be avoided if an expert was involved before the first concrete pour? The answer is quite a few. Engaging a consultant early during design review or preconstruction can prevent defects by identifying risk factors upfront. These might include soil inconsistencies, drainage challenges, or coordination gaps between trades.

Practical prevention strategies include routine peer reviews, quality audits, and third-party verification of high-risk installations. Experienced experts can help establish quality control benchmarks and conduct targeted inspections at critical stages. For comprehensive oversight across diverse scopes, construction discovery experts offer ongoing support from pre-bid evaluation through project closeout.

Conclusion: Partnering with Expert Witnesses for Construction Defect Success

Construction defect cases are rarely simple. They intertwine engineering, law, and human judgment. Yet with the right expert guidance, the fog clears. A trusted witness connects technical truth with legal clarity, helping stakeholders reach fair, defensible outcomes.

Whether you’re an attorney preparing a case or a contractor seeking answers, expert analysis can mean the difference between uncertainty and resolution. If you need help with complex defect claims or proactive consulting, reach out to a heavy equipment and construction expert witness today. Our team is ready to help you diagnose issues, document findings, and defend your project with confidence. Contact us to discuss your situation and next steps.