Every construction project is a puzzle of people, machines, materials, and timelines. When an accident or delay happens, the question isn’t just *what went wrong*, it’s *why* and *how* it can be prevented next time. That’s where incident analysis comes in. In the high-stakes world of civil, heavy, and underground construction, understanding the chain of events behind a failure isn’t just about fixing mistakes, it’s about protecting lives, budgets, and reputations.

At its core, construction incident analysis is the disciplined process of piecing together facts, evidence, and technical insight. It uncovers the causes behind incidents ranging from trench collapses and heavy equipment failures to scheduling disruptions and utility strikes. The result? Clear answers, accountability, and better practices for the future.

If your project involves complex underground or heavy construction, visit our dedicated page on civil, heavy, and underground construction delay cause and analysis to learn how our experts approach these investigations.

What Is Incident Analysis in Construction?

Imagine a deep excavation project that suddenly halts due to a trench collapse. The immediate response might focus on removing hazards and ensuring safety. But once the dust settles, stakeholders need to know what led to that failure. That’s where incident analysis begins. It’s not a guessing game, it’s a structured, evidence-based examination of facts, decisions, and conditions that converged at the point of failure.

Construction incident analysis often involves gathering documentation, interviewing witnesses, reviewing design and procedural documents, and comparing actions against industry standards. It aims to determine both the proximate cause (the immediate trigger) and the root cause (the underlying failure in systems, training, or oversight). When telecommunications or electrical lines are involved, for instance, an expert review of as-built drawings and one-call tickets can reveal whether the damage stemmed from inaccurate mapping or improper excavation depth.

Understanding Root Cause Analysis

Root cause analysis takes the investigation one step further. It seeks patterns, not isolated errors. Was maintenance overlooked? Were safety briefings rushed? Did weather alter soil stability? Tools like fault-tree analysis and the 5-Whys method help experts trace problems back through each decision layer until the true cause becomes clear. The findings often reshape safety plans and contract administration moving forward.

Common Causes of Incidents in Heavy and Underground Construction

1. Equipment and Machinery Failures

Heavy machinery is the backbone of construction, but also a frequent source of incidents. Equipment failure might trace back to improper maintenance, incorrect rigging, or even overlooked manufacturer advisories. Reviewing maintenance logs and operator training records can make the difference between identifying negligence and uncovering a systemic issue. Discovery Experts offers specialized heavy equipment litigation support to help determine whether the machine or method was at fault.

2. Environmental and Site Conditions

Underground work doesn’t always go as planned. Soil instability, water infiltration, or confined spaces can turn routine excavation into a hazardous environment. Even a subtle change in groundwater levels can compromise shoring systems. Thorough analysis considers not only design drawings but also real-world field conditions that evolve as projects progress.

3. Human and Procedural Factors

Many incidents boil down to human judgment. A skipped inspection, a misread plan, or an unapproved field modification can trigger costly failures. Often, procedural shortcuts made “to save time” create long-term consequences. Understanding the communication chain, who knew what, and when, is just as vital as technical testing. These insights shape both accountability and future prevention.

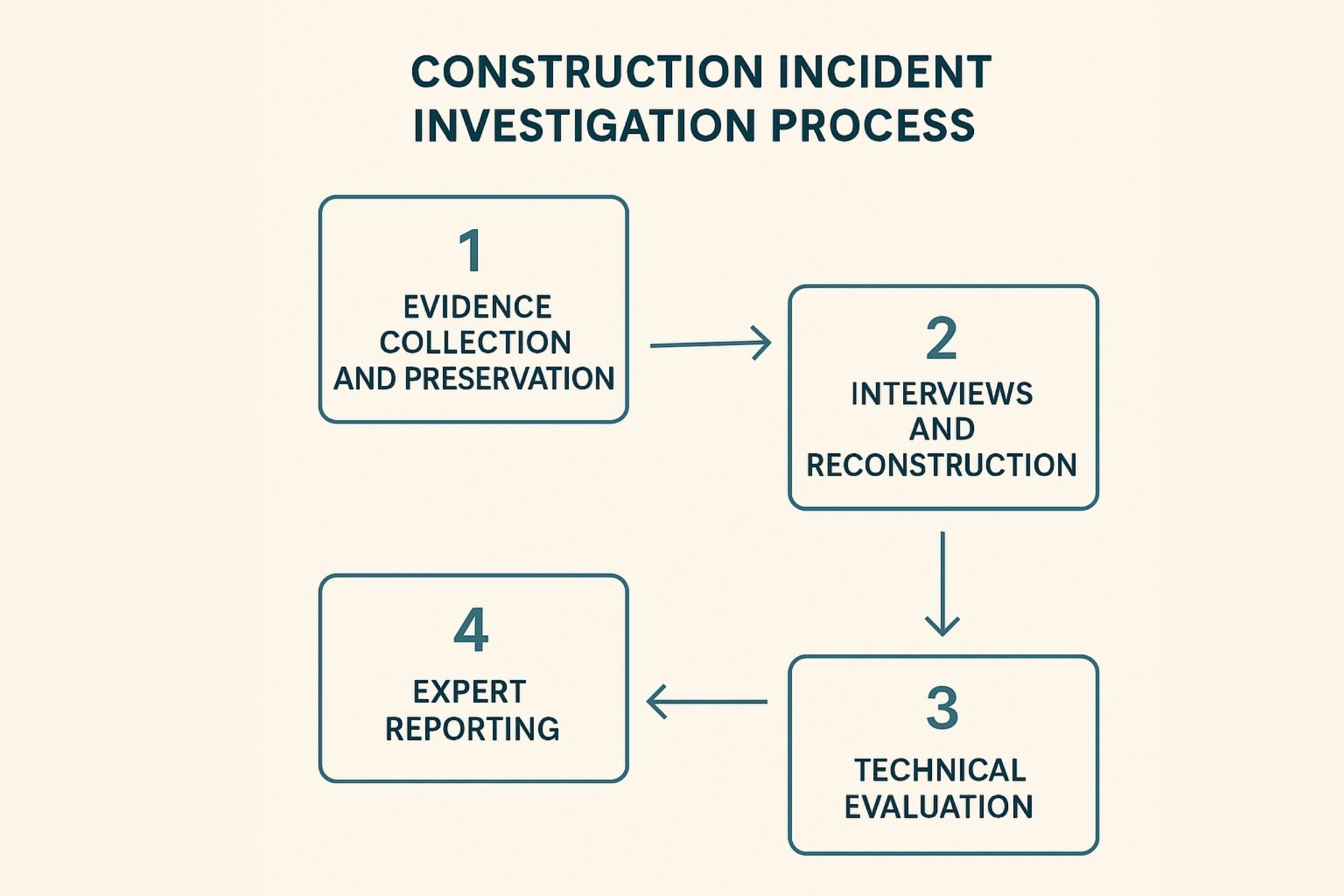

Steps in a Professional Construction Incident Investigation

Every professional investigation follows a deliberate path from evidence to conclusion. The process is designed not only to uncover facts but to make them defensible in both engineering and legal contexts.

Step 1: Evidence Collection and Preservation

Investigators document the scene immediately, taking photographs, securing damaged components, and collecting site measurements. They also review daily logs, safety reports, and inspection records. For trenchless operations, video footage and drilling logs can reveal subsurface conditions invisible to the eye. Learn more about our trenchless construction site inspection capabilities to see how these methods protect critical data.

Step 2: Interviews and Reconstruction

Recreating the sequence of events means combining human testimony with factual documentation. Interviews with operators, supervisors, and witnesses bring essential context, helping experts align the technical story with the real-world actions that unfolded on site.

Step 3: Technical Evaluation and Expert Reporting

Next, engineers evaluate actions against accepted standards such as OSHA, ANSI, and ASME. They may calculate trench pressures, load capacities, or equipment stresses to confirm or rule out contributing factors. When patterns emerge, experts prepare reports with clear findings, timelines, and evidence references. These reports often form the backbone of mediation, arbitration, or courtroom exhibits.

Discovery Experts maintains a detailed, transparent process for preparing these deliverables, as showcased in our construction discovery experts overview.

The Role of Expert Witnesses in Construction Incident Cases

When incidents escalate into disputes or litigation, expert witnesses bridge the gap between technical facts and legal arguments. Their role is to clarify, not advocate, to explain complex engineering realities in ways that judges, juries, and attorneys can understand. An effective expert’s testimony doesn’t rely on opinion alone; it’s grounded in evidence, methodology, and professional experience.

For example, an expert might illustrate how a small procedural deviation, say, skipping a soil test, cascaded into a multi-million-dollar failure. By walking the court through design documents, inspection photos, and engineering standards, the expert transforms abstract data into a clear, credible narrative. That clarity often influences settlements or verdicts.

Deliverables That Strengthen Legal Strategy

Comprehensive expert witness services typically include:

- Detailed causation analysis and issue lists

- Annotated construction timelines

- Equipment and materials evaluations

- Deposition and mediation support

Each product is crafted to withstand scrutiny and enhance the credibility of your legal case.

Best Practices to Prevent Future Construction Incidents

So, what lessons emerge from all this analysis? The best construction teams treat every incident as a learning opportunity rather than an isolated event. Prevention starts with integrating risk awareness into every phase, from bid to closeout.

Close the feedback loop. Once a root cause is identified, corrective actions must be implemented and tracked. That might mean rewriting a trenching checklist, revising lifting plans, or scheduling additional training. The key is to make prevention part of daily operations, not just a post-incident exercise.

Prepare for the unpredictable. Subsurface conditions can change quickly. Smart contractors set thresholds for when to pause work: ground movement, water seepage, or air quality readings. Incorporating conservative safety margins for utilities like fiber optic or electrical lines drastically reduces risk and protects surrounding infrastructure.

Turning Findings into Lasting Change

Documentation is only half the battle. Teams must communicate findings across departments, track completion of action items, and revisit them periodically. A strong safety culture grows from transparency, accountability, and follow-through.

Why Choose Discovery Experts for Construction Incident Analysis

With decades of combined experience across civil, heavy, and underground projects, Discovery Experts brings both field knowledge and analytical precision. Our specialists are engineers, construction managers, and industry professionals who have worked on real job sites, not just in theory. We believe that credible analysis begins with understanding how projects actually function day to day.

We integrate practical expertise with forensic methodology to produce findings that hold up under scrutiny. Whether the issue involves scheduling delays, equipment failure, or safety compliance, our approach remains the same: meticulous, factual, and unbiased.

Explore our work on civil, heavy, and underground construction delay cause and analysis, review our heavy equipment litigation support expertise, or learn about our trenchless construction site inspection services. When you’re ready to discuss your case or project, contact Discovery Experts for a confidential consultation.

Conclusion

Every incident tells a story. The difference between confusion and clarity lies in how that story is investigated and interpreted. With structured analysis, projects can emerge stronger, safer, and better informed. For the construction industry, incident analysis isn’t just about finding fault, it’s about building a culture of continuous improvement.

Discovery Experts stands ready to help you uncover the truth, learn from it, and move forward with confidence. Whether you need technical insight, litigation support, or expert testimony, our team is here to provide the precision and professionalism your case demands.